We Provide 1TPH to 100TPH Biomass Pellet Plant Production Line Turnkey Project That Will Produce Pellets With the World Standard Technologies!

Biomass pellet plant production line offers a sustainable solution to waste management. Many organic materials used in biomass pellet production, such as agricultural residues and wood waste, are by-products of other industries. By converting these waste materials into biomass pellets, they can be put to productive use instead of being disposed of in landfills or burned in an uncontrolled manner. This reduces the environmental impact of waste and promotes a circular economy.

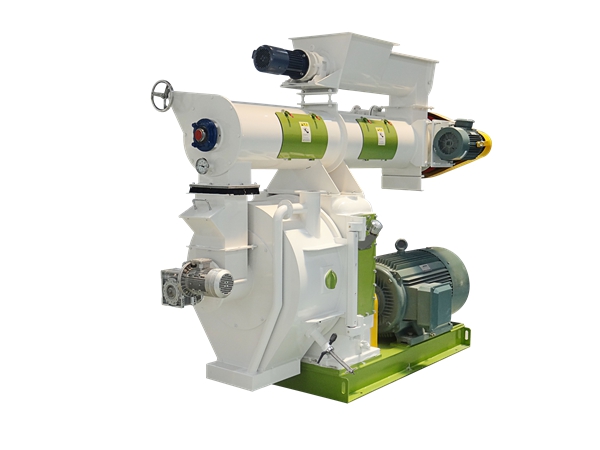

Biomass pellets is commonly make by biomass pellet machine with the biomass materials. Before turning into pellets,a series of processes, including crushing to required size, drying to reduce water content, pelletizing, cooling and sifting, packaging and palletizing etc. It is normally including pre-cleaning machine, hammer mill, wood chipper, dryer machine, pellet machine, cooler, sifter, packing machine, pulse filter, bucket elevator, screw conveyor, belt conveyor,fan, airlock, cyclone etc. After processing, the combustion and automation operation performance of biomass materials has been increased sharply. With features of high combustion value,uniform size, biomass pellets have wide range application in boiler, power plants, factories and household heating,etc. As the biomass energy is recognized by more and more people, biomass pellets shares an increasing percent in fuel market.That is to say, biomass pellet industry is a sunrise industry which is worth investing.