مقدمة إلى مجففات الكتلة الحيوية: ما هي وكيف تعمل

Biomass dryers are an important tool for the efficient and cost-effective processing of biomass materials. They are used to reduce the moisture content of biomass materials, such as wood chips, sawdust, and agricultural residues, to a level that is suitable for further processing. This process is essential for the production of a wide range of products, including pellets, briquettes, and biofuels.

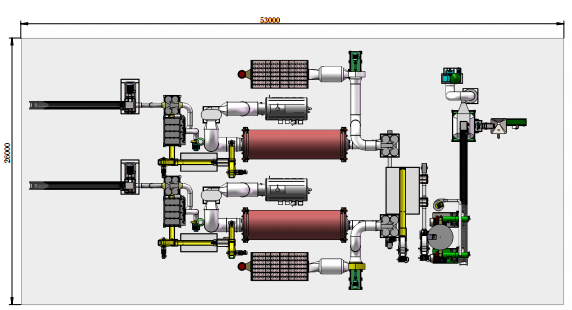

Biomass dryers come in a variety of designs and sizes, but all share the same basic principles of operation. The most common type of biomass dryer is the rotary drum dryer. This type of dryer consists of a large rotating drum that is heated from the inside by a heat source. As the drum rotates, the biomass material is fed into the drum and is exposed to the hot air inside. The hot air evaporates the moisture from the biomass material, leaving it dry and ready for further processing.

Other types of biomass dryers include flash dryers, belt dryers, and fluidized bed dryers. Flash dryers use hot air to quickly evaporate the moisture from the biomass material. Belt dryers use a conveyor belt to move the biomass material through a heated chamber, where the moisture is evaporated. Fluidized bed dryers use a bed of hot sand or other material to evaporate the moisture from the biomass material.

No matter which type of biomass dryer is used, the process is the same. The biomass material is exposed to hot air, which evaporates the moisture from the material. This process reduces the moisture content of the biomass material to a level that is suitable for further processing.

Biomass dryers are an essential tool for the efficient and cost-effective processing of biomass materials. They are used to reduce the moisture content of biomass materials to a level that is suitable for further processing, allowing for the production of a wide range of products.