Sawdust Dryer Machine Factory Price For Sale

sawdust dryer machine, we also called sawdust drying machine or biomass drum dryer. Available mainly raw materials: sawdust or grinded wood powder. Available other powder biomass materials: straw, rice husk, alfalfa, peanut shell, palm nut, coconut shell,cotton seed, elephant grass,sugar cane,pulp .etc.

Features for sawdust dryer machine

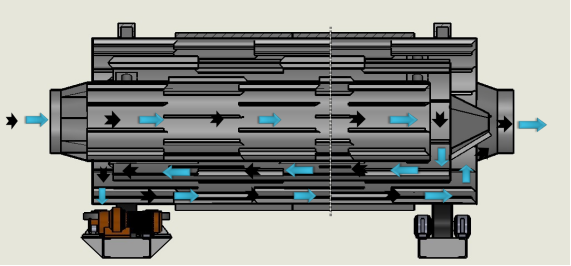

1.Three-pass dryer, longer mixing duration of hot air and material. With high drying efficiency,heat utilization ratio, less space needed.

2.Support of roller ring and retainer wheel are integral cast steel structure, with high strength,stable operation and long service time.

3.Feeding device is separately designed, which is convenient for installation and transportation.The drum of dryer can be designed to fit the transportation in the containers.

4.Convenient feeding: feeding from middle of dryer by screw conveyor or from the top based on the different materials.

5.Sealed by flexible and anti-abrasion steel disc at the drum body and feeding &discharge end, with long service life.

6.Lifting plates installed inside the drum makes the material fully mixed with the hot air,with low residue and high drying efficiency.

7.Reasonable discharge structure that can separate hot air and material efficiently.

8.Thermal insulation set at outer layer of drum can effectively prevent the heat from losing and improve the utilization efficiency.

9.Three layers drum dryer’s floor space is 30% less than single drum dryer with same capacity.

10.Siemens motor.

Application

sawdust dryer machine, we also called sawdust drying machine or biomass drum dryer. Available mainly raw materials: sawdust or grinded wood powder. Available other powder biomass materials: straw, rice husk, alfalfa, peanut shell, palm nut, coconut shell,cotton seed, elephant grass,sugar cane,pulp .etc.

Working principle

By the main Speed reducer drive chain and sprocket, the drive shaft through the speed reducer to drive, The friction wheel is installed on the driving shaft ,That meshes the friction ring is fixed on the machine body, opposite work ,driving drum rotation. the material from the feed inlet to join, through the drum rotating and the wind blowing force, inside the cylinder body “S” type to the discharge end.Hot air produced by hot stove (With the use of machine) into the inside of the cylinder by gravitation of the fan, Lifting plate flips material constantly , under the action of wind, mix with wind blown transport, In this process, The hot air and the material is fully exposed to achieve uniform drying purposes.Dried material with high speed air flow outflow from the outlet.

Technical Parameters

Model | YLHG1 | YLHG2 | YLHG3 | YLHG4 | YLHG5 |

Body inside dia.(mm) | 1700 | 2450 | 2650 | 2850 | 3700 |

Body Length(mm) | 8000 | 8000 | 9000 | 9000 | 10000 |

Capacity(t/h) | 1-2 | 2-3 | 3-5 | 4-6 | 5-8 |

Inlet temperature(℃) | <500 | <500 | <500 | <500 | <500 |

Raw material | Sawdust | Sawdust | Sawdust | Sawdust | Sawdust |

Moisture(%) | 45 | 45 | 45 | 45 | 45 |

Outlet temperature(℃) | 80 | 80 | 80 | 80 | 80 |

Power(kw) | 2.2×2 | 3×2 | 4×2 | 4×4 | 5.5×4 |

Compostion of the sawdust dryer machine

The sawdust dryer machine is YONGLI high Quality Patented products. It consists of four parts: furnace, drum, negative pressure system, and electrical control.

1. The furnace part includes: furnace body, grate, furnace door, flue, and settling chamber. The outer periphery of the furnace body is made of steel frame and bricks; the interior is made of high-temperature resistant bricks and mud. The grate and furnace door are cast iron equipment. The settling chamber consists of two parts. The first is a settling chamber made of refractory bricks, and the second is a settling chamber made of Q235-A material or SS material. The purpose of the two settling chambers is the same: to settle the ash and sparks in the hot air. Because the ash will pollute the material, and the sparks may cause fire when they enter the drum and contact the material, so two settlings must be used to deal with the ash and sparks! The hot air of the furnace enters the drum through the heat-insulating flue.

2. Drum Body. The drum is composed of a feed conveyor, a head drum body, and a tail and discharge conveyor. The feed conveyor is controlled by frequency conversion and can adjust the speed. Its main function is to convey the materials to be dried to the drum according to the computer needs! The function of the head is to connect the feed conveyor with the drum, the furnace with the drum body. The function of the drum body is to provide a space for the material to mix with the hot air, exchange heat, and evaporate water. The drum itself can be turned over, and there are many copying plates on its inner wall, which can keep the material rolling in the air so that the material and the hot air are fully mixed. The drum will have a certain inclination when installed. When the material contacts the hot air, it is inversely proportional to the rotation speed of the drum, so the rotation speed of the drum is controlled by the computer. The tail is a mechanism that connects the negative pressure system with the drum, and the drum with the discharge conveyor.

3. The negative pressure system includes fans, cyclone, dust filters, and air lock pipes. Its function is to guide the airflow movement, separate the materials in the airflow after drying, and send them to the conveyor, and discharge the clean air into the atmosphere. Among them, the fan is variable frequency and its wind speed is controlled by the computer.

4. Electrical control. The electrical system consists of temperature sensors, moisture meters, PLC, frequency converters and some conventional control components. The moisture meter measures the moisture of the raw materials before drying and the moisture of the dried materials. The temperature sensor measures the temperature of the hot air output by the furnace and the temperature of the hot air after drying! A moisture meter and a temperature sensor are installed at the raw material entry point of the dryer; a moisture meter and a temperature sensor are installed at the dryer outlet. The PLC calculates and controls the feed speed, drum speed and wind speed of the negative pressure system based on the temperature difference between the two temperature sensors and the moisture difference of the moisture meter.

Video for Sawdust Dryer Machine