Introduction to Bagasse Pellet Machine System

Bagasse, the fibrous residue left after sugarcane stalks are crushed to extract their juice, has long been considered a waste product. However, with the increasing demand for renewable energy sources, bagasse has gained attention as a potential biomass fuel. Bagasse pellets, made from compacting and extruding bagasse fibers, have become a popular choice for heating and power generation. In this article, we will guide you through the process of building a complete bagasse pellet machine system.

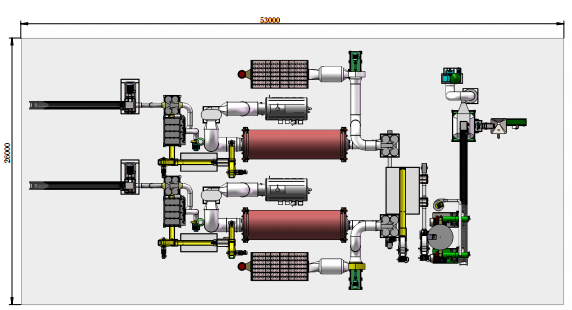

To begin with, it is important to understand the components of a bagasse pellet machine system. The main equipment includes a bagasse pellet mill, a dryer, a conveyor, and a pellet cooler. The bagasse pellet mill is the heart of the system, responsible for transforming bagasse fibers into compact pellets. The dryer is used to reduce the moisture content of the bagasse, ensuring optimal pellet quality. The conveyor is used to transport the bagasse from one machine to another, while the pellet cooler is used to cool down the pellets after they are formed.

The first step in building a bagasse pellet machine system is to select the right equipment. It is crucial to choose a bagasse pellet mill that is capable of handling the desired pellet production capacity. Factors to consider include the power of the motor, the size of the die, and the overall design of the machine. Additionally, it is important to choose a dryer, conveyor, and pellet cooler that are compatible with the chosen pellet mill.

Once the equipment has been selected, the next step is to set up the system. The bagasse should be properly prepared before it can be fed into the pellet mill. This involves shredding the bagasse into smaller pieces and removing any impurities. The bagasse is then fed into the pellet mill, where it is compressed and extruded through the die to form pellets. The pellets are then transported by the conveyor to the dryer, where they are dried to reduce their moisture content. Finally, the pellets are cooled down in the pellet cooler before they can be stored or used.

It is important to note that building a bagasse pellet machine system requires careful planning and consideration. Factors such as the availability of bagasse, the desired pellet production capacity, and the available space for the equipment should all be taken into account. Additionally, it is important to ensure that the system is properly maintained to ensure optimal performance and longevity.

Building a complete bagasse pellet machine system is a complex process that requires careful planning and consideration. By selecting the right equipment and properly setting up the system, it is possible to transform bagasse into high-quality pellets for heating and power generation. With the increasing demand for renewable energy sources, bagasse pellets offer a sustainable and efficient solution. So, if you are considering building a bagasse pellet machine system, make sure to follow the steps outlined in this article to ensure success.