Showing 61–72 of 78 results

-

Vibrating Screener:

It is a very suitable for grading and screening all kinds of pellets.

-

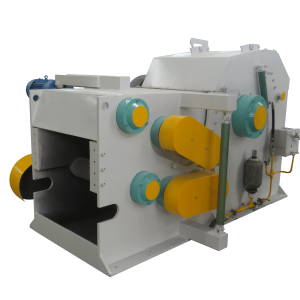

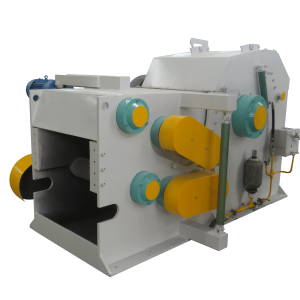

- Available raw material: wood logs ,branches and twigs with moisturemore than 15%.

- Special material blade, with high strength and anti-abrasion.

- Free of any professional tool sharpener, low maintenance cost. It is our patent product.

- Knife roll is wholistic processing and is undertake dynamic balance test to improve accuracy and stable operation.

- It can process larger diameter wood with its special structure.

- Squeezing parts is automatic controlled by hydraulic system, feeding system can be frequency controlled.

- Forging dead plate, with high strength and long service time.

- Patented knife roll structure, slice efficiency by 30% -50%

-

- CNC processing, with high accuracy

- Special process of hammer, with long service time

- Siemens motor and SKF bearing

- It adopts steel plate welding structure, the rotor of the crusher and the motor are installed on the same base, and the direct transmission is carried out by a pin coupling, which has high transmission efficiency.

- The rotor of the crusher is checked by dynamic balancing, so that the rotor works smoothly and can work in forward and reverse directions.

-

Wood Log Diameter: 20-500mm

Capacity:3-30T/H

-

It is mainly used for cooling of pellet in the biomass pelleting section. It cools the pellet coming from pellet mill and with a temperature 70~ 90℃ to a temperature 3~5℃ slightly higher than ambient temperature, and is capable of lowering to a safety moisture content. Th cooled pellets not only improve the pellet firmness but also can prevent from going mouldy, that it is good for the transportation and storage of pellet.

-

Biomass wood pellets have wide range application in boiler, power plants, factories and household heating, wood processing plant etc.

-

- High Strength.

- Reliable Sealing.

- Short Construction Cycle.

- Beautiful Appearance.

- Long Service Time.

-

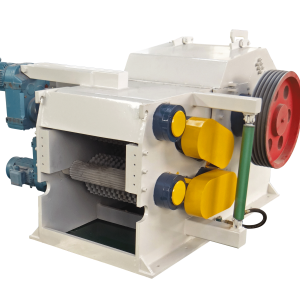

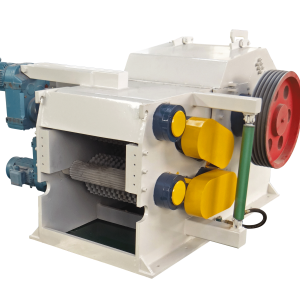

- CNC processing, with high accuracy

- Special process of hammer, with long service time

- Siemens motor and SKF bearing

- It adopts steel plate welding structure, the rotor of the crusher and the motor are installed on the same base, and the direct transmission is carried out by a pin coupling, which has high transmission efficiency.

- The rotor of the crusher is checked by dynamic balancing, so that the rotor works smoothly and can work in forward and reverse directions.

-

Wood Hammer Mill is a kind of crusher machine to turn wood logs, tree branches, wasted wood, wood residues, trunk into sawdust. It adopts steel plate welding structure, the rotor of the crusher and the motor are installed on the same base, and the direct transmission is carried out by a pin coupling, which has high transmission efficiency.

-

Automatically feeding and continuously operation, free of labor force and widely application.

-

YLBX950 Factory Directly 3 to 5ton per hour 55kw disc Wood Chipper Crusher

-

- High drying efficiency

- integral cast steel structure

- Convenient feeding, from middle or from top

- Siemens motor