2T/H Soft Wood Pellet Production Line

2T/H Wood Pellet Production Line

Raw materials: Wood, woochips etc

Project brief introduction for 2T/H Soft Wood Pellet Production Line

- Raw materials: Wood,woodchips

- Capacity:2t/h

- Pellet size: 6mm

- Pellets Package: 15kg/bag

- Pellet machine: YPM520, Total 1pcs

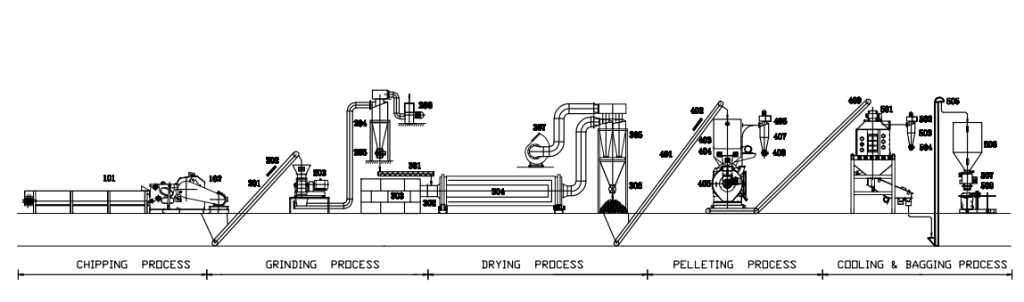

Drawing for 2T/H Soft Wood Pellet Production Line

Onsite pictures for 2T/H Soft Wood Pellet Production Line

(1)Chipping Process

In the pellet plant before raw materials are made into biomass pellets, they are first reduced into much smaller, uniformly-sized particles. When the thick is larger than 10mm or the size is greater than 50*50mm, a chipper is needed to chip these materials into smaller pieces.

(2)Grinding Process

The hammer mill is used to further crush these small pieces into particles of less than 3mm in diameter.

(3)Drying Process

After raw materials are crushed, a dryer is needed since most raw wood materials have high moisture content. Since the optimal moisture content for pellet is 13%-15%. Therefore a biomass dryer is needed in the pellet plant to reduce the moisture content.

(4)Pelleting Process

The pelleting machine is the key piece of machinery in the pellet plant.

(5)Pellet Cooling and Pellet Siftering Process

Usually after pelleting, the temperature of pellets is between 60-80 degrees and the moisture content is close to 15%. For storage purpose, a cooler must be used to reduce their surface temperature and moisture content.

(6)Pellet Packing Process

In order to protect the wood pellets becoming getting damp and to increase stability, proper packing is necessary.

You can choose small bag packing and ton bag packing, depends on your market requirement.

shipment Video