China Factory Price Wood Peeling Machine

Widely used for different kinds of timber, can process different species of wood with different diameter, length and shape , since the rotational movement of the wood and irregular beating, so the curved recess portion and the wood can touch teeth contacts. Therefore, the net rate of bending wood stripping is much higher than other rotary style peeling machine.Due to the huge cabinet is stationary, so the energy consumption and failure rate is lower,need less maintenance, vibration and noise is much lower than the rotary peeling machine,work directly after installation , even without base frame, easy to use.

China Factory Price Wood Peeling Machine

Widely used for different kinds of timber, can process different species of wood with different diameter, length and shape , since the rotational movement of the wood and irregular beating, so the curved recess portion and the wood can touch teeth contacts. Therefore, the net rate of bending wood stripping is much higher than other rotary style peeling machine.Due to the huge cabinet is stationary, so the energy consumption and failure rate is lower,need less maintenance, vibration and noise is much lower than the rotary peeling machine,work directly after installation , even without base frame, easy to use.

Features of wood peeling machine

- Available raw material: wood logs with barks.

- Famous brand tooth surface, with high driving efficiency and long service time.

- Debarker roller is directly connected with reducer, with stable operation,easy maintenance.

- Debarking knived are arranged in screw type, with high debarking efficiency.

- Equipped with belt conveyor at the bottom of wood debarker, it setsto collect&convey barks.

- Seperated type side board, itmakes maintenance more convenience.

- It could be customized accarding to raw material diameter and length.

- Continously operation allowed.

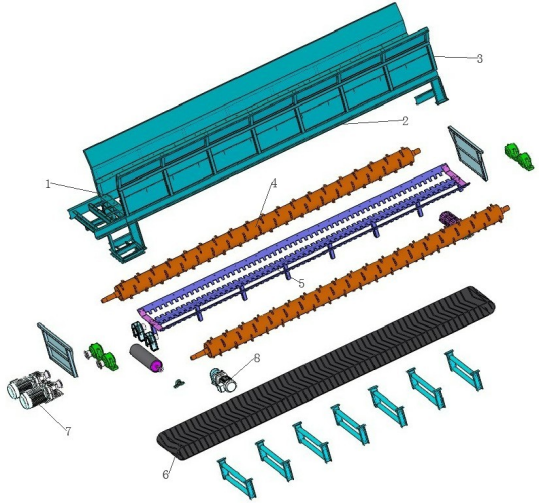

The main structure of wood peeling machine

YLMB-Z series wood peeling machine contains peeling rollers, feed inlet, bark outlet, wood outlet,power drive,..etc.

Technical Parameters

Model | Capacity(t/h) | Diameter range(mm) | Peeled rate | Timber loss rate | Timber length | Power of main motor(kw) |

YLMB-Z600I | 3~6 | 20-500 | >95% | <2% | <6m | 11 |

YLMB-Z900I | 6~10 | 20-500 | >95% | <2% | <9m | 15 |

YLMB-Z1200I | 10~15 | 20-500 | >95% | <2% | <12m | 22 |

YLMB-Z600II | 7~12 | 20-500 | >95% | <2% | <6m | 7.5*2 |

YLMB-Z900II | 12~22 | 20-500 | >95% | <2% | <9m | 11*2 |

YLMB-Z1200II | 22~30 | 20-500 | >95% | <2% | <12m | 15*2/18.5*2 |

Working principle For wood peeling machine

Double roller, single roller wood peeling machine is a new generation of efficient wood peeling machine developed by our company, The machine take the force produced by the teeth of the rotor, so that the wood in the tank plate can circulate,also circulate around the axis, logs themselves do rotary motion and irregular beating.So, the wood and the machine teeth, wood and wood, wood and tank,full of friction, impact, compression,so the bark is separated rapidly,achieving efficient peeling effect.

Project Case