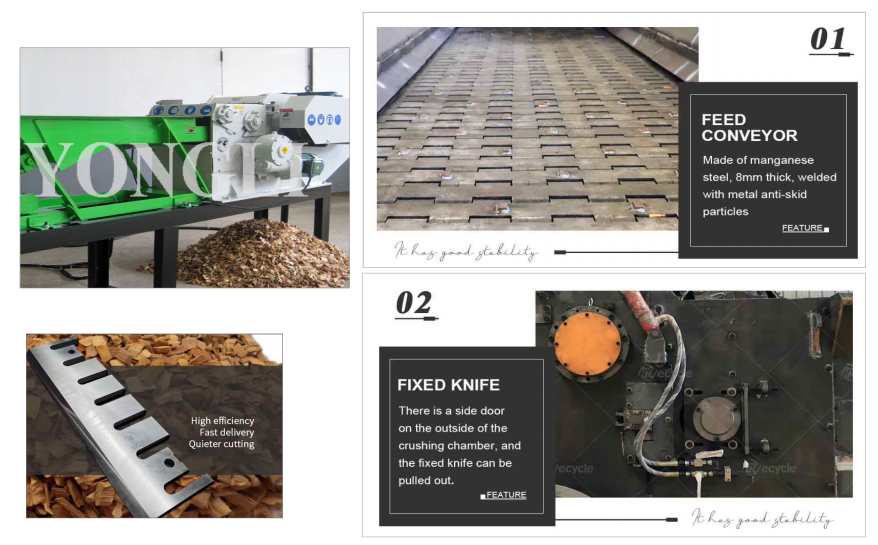

High capacity 45-55T/H Wood Chipper Shredder

Wood chipper shredder is an ideal chipper machine to process wood logs, wood timber, bamboo, watse wood into wood chips. It equipped with feeding system equipment, the body of wood chipper shredder, bracket belt conveyor, Electrical Control system, hydraulic system, etc.It is very easy to operate.

Wood chipper shredder

Wood chipper shredder is an ideal chipper machine to process wood logs, wood timber, bamboo, watse wood into wood chips. It equipped with feeding system equipment, the body of wood chipper shredder, bracket belt conveyor, Electrical Control system, hydraulic system, etc.It is very easy to operate.

Description for YLBX1318, capacity 45-55T/H Wood Chipper Shredder

1.Chain plate machine length 5m, feeding width: 1800mm

2. Main power: 315kw, discharge belt conveyor power: 7.5KW.

3.Feeding motor power: 18.5*2KW, hydraulic oil pump motor: 4KW

4. Knife roller diameter: 1300mm

5. Host inlet size: 1800mm *1000mm (width * height)

6. Knife roller speed: 650rpm

7. Number of blades: 9 pieces, blade size: 650mm*220mm*20mm

8. Discharge belt conveyor length: 12m, height from the ground: 4500mm

9. Including electrical control cabinet, frequency conversion feeding.

10. Motor: Siemens, bearing: SKF

11.Capacity: 45-55T/H

Feeding system equipment for Wood Chipper Shredder

There are two types of feeding devices: belt conveyors or vibrating feeders. A belt conveyor consists of a head wheel, a tail wheel, a belt, and a frame. The head wheel is driven by the lower feeding roller shaft through a chain. The head wheel drives the belt to feed the raw materials into the feeding port.

The belt includes single or multiple layers, made of polyesters/polyamides, coated with rubber or PVC strong adhesive.

The belt is white or black, resistant to grease and gasoline, wear-resistant and anti-static.

The vibrating feeder consists of a material trough, a base, and a driving part. The crank connecting rod mechanism is driven by an electric motor separately, and due to eccentric rotation, the material groove is driven for intermittent vibration, causing the raw material to move forward in the groove and enter the feeding port.

| 1 | Feeding type | Chain feed |

| 2 | Feeding motor power | 18.5KW+18.5KW,4P,variable frequency feed |

| 3 | Feeding trough length | 5000mm, outer eight type |

| 4 | Feeding trough thickness | 10mm |

| 5 | Reducer | Hard tooth surface R107 |

| 6 | Feeding speed | 33m/min |

| 7 | Upper forced feeding roller | Diameter 900 |

| 8 | Lower feeding roller | Three rows of feed rollers, each with a diameter of 316 |

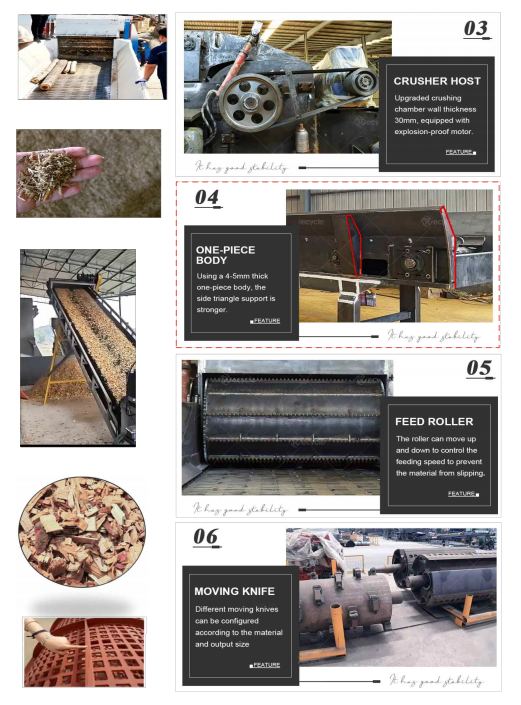

The machine of wood chipper shredder

| 1 | Main machine boring | The whole machine is boring, and the equipment has good concentricity |

| 2 | Main machine steel plate thickness | 35mm, (the inner lining plate is 25mm thick) |

| 3 | Main machine plate | Q235B |

| 4 | Diameter and width of knife roller | 1300mm, 1800mm tool holder full sleeve |

| 5 | Knife roller speed | 650rpm |

| 6 | Production capacity | 45-55T/H |

| 7 | Feed port | 1800*1000mm |

| 8 | Number of blades | 9 pieces |

| 9 | Blade size | 650mm*220mm*20mm |

| 10 | Main power/power | 315KW |

| 11 | Main machine and feed dimensions | 9600mm*3225mm*3100mm |

| 12 | Total machine weight | 22T |

| 13 | Bearing | Main bearing 23136CAK/33, SKF |

| 14 | Main shaft material | Spindle 40Cr quenching and tempering |

Discharging system equipment

The discharge device can take various forms, such as airflow conveying, chain scraper conveyor conveying, belt conveyor conveying, bucket elevator conveying, and so on. The discharge method is determined based on the production process layout. However, regardless of the form used, the output of the wood chips from the discharge device must be suitable for the production capacity of the chipper, that is, the cut wood chips must be able to be output in a timely manner without causing blockages. When using airflow for transportation, this should be paid more attention to.

| No. | Item | Bracket belt conveyor |

| 1 | Motor power | 7.5KW |

| 2 | Outfeed belt width and length | 1600mm, 12m |

| 3 | Tape material | 5-layer nylon (10mm thick) |

| 4 | Head unloading height | 4500mm |

| 5 | Outfeed length | 12m |

| 6 | Outfeed rack channel steel | 14-gauge double-jointed channel steel |

Electrical Control system for wood chipper shredder

| No. | Item | Electrical Control |

| 1 | Control box model | RQ-900-400 |

| 2 | Frequency conversion feeding | Feed start and stop, total stop, pressure maintenance |

Hydraulic system for wood chipper shredder

The hydraulic buffer system consists of an oil pump, large and small oil cylinders, a one-way throttle valve, an accumulator, valves, and other pipeline components.

The oil pump supplies oil to the small oil cylinder and can activate the cover; Oil supply to the large oil cylinder can lift or reduce the weight of the pendulum. The accumulator plays a role in storing energy and mitigating impacts, ensuring smooth lifting and lowering of the pendulum.

| No. | Item | Hydraulic system |

| 1 | Hydraulic oil tank capacity | 45L |

| 2 | Hydraulic oil pump motor | 4KW |

| 3 | Hydraulic oil pump model | 4WE10D31B |

Video of wood chipper shredder machine