Wood Crushing Machine

- CNC processing, with high accuracy

- Special process of hammer, with long service time

- Siemens motor and SKF bearing

- It adopts steel plate welding structure, the rotor of the crusher and the motor are installed on the same base, and the direct transmission is carried out by a pin coupling, which has high transmission efficiency.

- The rotor of the crusher is checked by dynamic balancing, so that the rotor works smoothly and can work in forward and reverse directions.

Wood crushing machine

Wood crushing machine is a kind of crusher machine to turn wood logs, tree branches, wasted wood, wood residues, trunk into sawdust. It is widely used by wood pelletizing plant, wood powder making,sawdust burning furnace., etc.

It adopts steel plate welding structure, the rotor of the crusher and the motor are installed on the same base, and the direct transmission is carried out by a pin coupling, which has high transmission efficiency.

The rotor of the crusher is checked by dynamic balancing, so that the rotor works smoothly and can work in forward and reverse directions.

Description

- 1.Available raw material: wood bricks , shavings, straw, peanut shell, palm shell ,cotton seed, bamboo dust, rice husk, elephant grass, sugar cane, pulp, olive dust, and so on.

- 2.Water drop structure , with high driving efficiency.

- 3.Siemens motor and imported bearing.

- 4.Directly connected motor,with high driving efficiency.

- 5.Maintenance gate is installed by rail structure,which is of simple and convenient operation.

- 6.Special process of hummer, with long service time.

- 7.U-shape grinding groove at the bottom of grinding chamber, with improvement of grinding efficiency of 50%-80%.

- 8.Dead knife optional that can improve the grinding efficiency.

- 9.Rotor is undertake dynamic balance test, which can ensure the stable operation and long service time.

- 10.Rotor rotating in clockwise and anti-clockwise direction can prolong the service life of hammers.

- 11.Screen fix mechanism is equipped with pressing handle, which makes more convenient of replacing of screen.

- 12.Diameter of screen can be determined according to the technological design.

- 13.CNC processing, with high accuracy.

- 14.Equipped with inspection and emergency stop device to protect the local worker from ant injuries.

Technical Parameters

Model | Diameter of rotor(mm) | Width of grinding chamber(mm) | Main shaft speed(rpm) | Hammer linear speed(m/s) | Hammer qty General smash(pc) | Hammer qty Fine grinding(pc) | Capacity(t/h) Generally Crushed(Screen diameter ≥θ6.0) | Capacity(t/h) Fine Crushed(Screen diameter ≤θ 1.0, more than 40 mesh) | Power(kw) |

YHM56*36 | 560 | 360 | 2950 | 86 | 20 | 40 | 1 | 0.1 | 22/30 |

YHM56*40 | 560 | 400 | 2950 | 86 | 24 | 48 | 1-1.5 | 0.2 | 30/37 |

YHM60*45 | 600 | 450 | 2965 | 94 | 48 | 80 | 1.5-2.5 | 0.3-0.5 | 55 |

YHM60*60 | 600 | 600 | 2970 | 94 | 64 | 88 | 2.5-3.5 | 0.5-0.8 | 75/90 |

YHM68*80 | 680 | 800 | 2970 | 107 | 88 | 88 | 4-5 | 0.9-1.5 | 110 |

YHM68*100 | 680 | 1000 | 2975 | 107 | 104 | 104 | 5-8 | 1.2-1.8 | 132 |

YHM68*120 | 680 | 1200 | 2975 | 107 | 120 | 120 | 8-10 | 1.5-2.5 | 160 |

Rotors, hammers and screens for Wood crushing machine

- 1.The rotor is dynamically balanced to ensure smooth operation and forward and reverse operation.

- 2.Strong and durable, high productivity, easy to operate, safe and reliable.

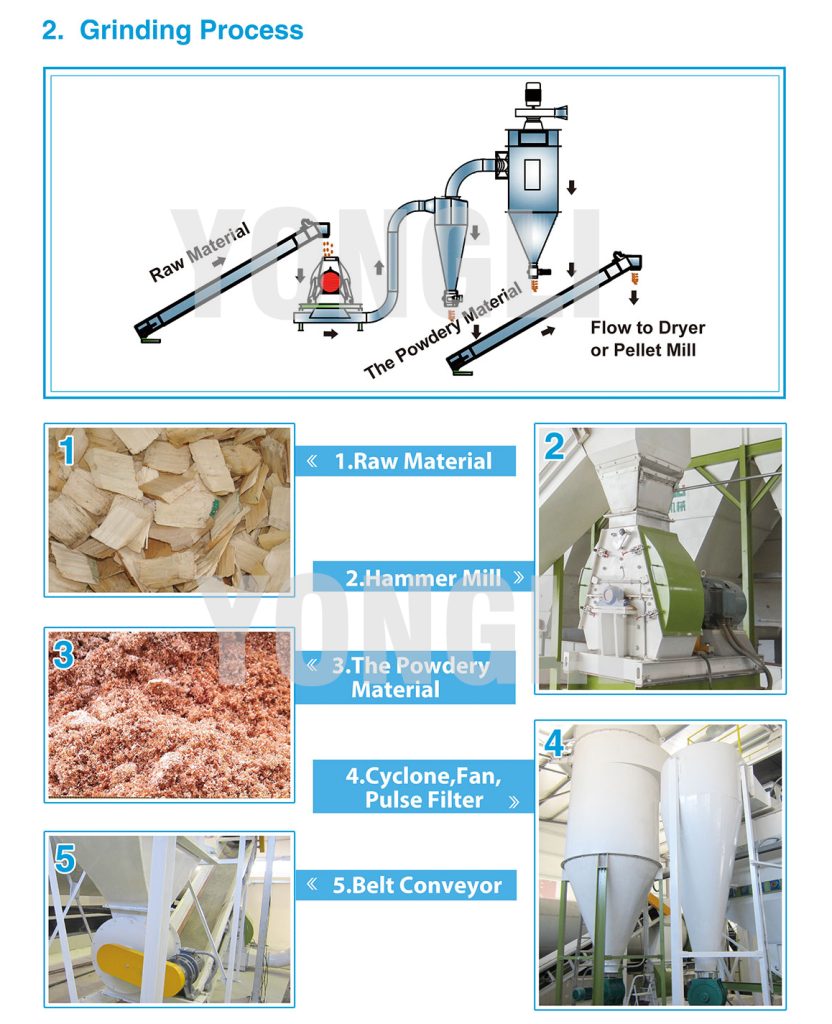

The grinding working process

The war material can be wood chips, wood logs, wood branches, coconut shells, bean stem, slab, bamboo, waste veneer, cotton stalk, and other biomass waste.The final size can adjustable by using different size sieves. The generally crushed screen diameter ≥∮6.0mm, the Fine crushed screen diameter ≤∮1mm.

Video

Contact with Yongli