In the process of wood pellet production, the crack in the keyway of ring die is an important problem, which not only affects the production efficiency, but also may bring security risks. After careful observation and analysis, we ruled out the ring die material and its heat treatment process as the cause of this problem. Judging from the cracking of the keyway, we found that the ring die was impacted during high-speed operation, so we speculated the factors that might lead to cracking.

Table of Contents

First, Cracking at the keyway of ring die

1. The hoop is not sufficiently fixed.

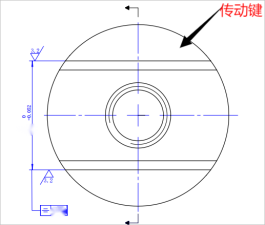

2. There is a gap between the keyway of the ring die and the drive key.

In order to solve this problem, we can take the following measures:

1)Ensure that the hoop is sufficiently fixed to prevent loosening and displacement of the ring die during operation.

2)Check whether there is a gap in the keyway of the ring die, and whether the transmission key is installed in place and worn, and repair or replace it in time.

3)Check the locking status of the hoop every shift and tighten it in time.

By taking these measures, we can effectively solve the problem of cracking in the keyway of the ring die of the granulator, improve production efficiency and product quality, and reduce production costs and safety risks. At the same time, we should also strengthen the awareness of equipment maintenance and maintenance, and regularly check and maintain the equipment to ensure the normal operation of the equipment and extend its service life.

Second, the middle of the granulator ring die cracking.

The cracking in the middle of the ring die of the granulator is a common fault of the granulator, which is usually caused by the use of the ring die for a long time, material fatigue, improper use or foreign matter entering the pressing chamber. When the ring mold cracks, it is necessary to take measures to repair it in time. First of all, the ring mold needs to be removed for inspection to determine the location and degree of cracking. If the crack is light, welding can be used to fill and strengthen it; If the crack is more serious, a new ring mold needs to be replaced.

In order to prevent ring mold cracking, the following measures can be taken:

1. Regular inspection of the ring mold: In the production process, it is necessary to regularly check the use of the ring mold, and timely find and repair cracks or problems.

2. Use high-quality materials: Choosing high-quality materials can increase the service life and fatigue resistance of the ring die, such as stainless steel.

3 Avoid overuse: Avoiding overuse of ring molds can reduce the risk of material fatigue and mechanical damage.

4. Strengthen the training of operators: Strengthening the training of operators can improve their skill level and understanding of the granulator, reducing the risk of improper use.

5. Use reinforcing ring to fix the outside of the ring mold, strengthen and protect the ring mold from external impact.

In short, cracking in the middle of the ring die of the granulator is a common failure, but it can be achieved through regular inspection, the use of high-quality materials. Reasonable adjustment of parameters, avoid overuse and strengthen the training of operators and other measures to prevent and solve.