YPM Series Rice husk Pellet Press

- YPM series rice husk pellet press is the continuous innovation and upgrading of Yongli machinery granulation equipment. Because of its stable structure, simple operation, high degree of intelligence, reliable operation, convenient maintenance, relatively low production and construction costs, it is widely used in particle treatment systems.

- In addition to rice husk, our equipment is also suitable for granulating straw, peanut shells, wood chips, waste wood, sawdust, branches, palm husks, bagasse and other granulation. Users can use one or more raw materials at a time for pellet processing.

Rice husk Pellet press

- YPM series rice husk pellet press is the continuous innovation and upgrading of Yongli machinery granulation equipment. Because of its stable structure, simple operation, high degree of intelligence, reliable operation, convenient maintenance, relatively low production and construction costs, it is widely used in particle treatment systems.

- In addition to rice husk, our equipment is also suitable for granulating straw, peanut shells, wood chips, waste wood, sawdust, branches, palm husks, bagasse and other granulation. Users can use one or more raw materials at a time for pellet processing.

Features Of Rice husk Pellet press

- 1.Forced feeder:Forced feeding into pelletizing chamber,make pellet mill operate stable and with high efficiency.

- 2.Gear reducer with Aluminum Alloy housing,wilth compact structure,altractive appearance and high driving efficiency.

- 3.Driven by gear,elegant and efficient gearbox grants pellet mill with high driving efficiency.

- 4.Lubrication system consists of automatic lubrication and manual lubrication. Automatic lubrication system:lubricated by thin oil and is free of labor force.Lubricate can automatically cool down during operation.Oil recycle used can cool the oil.Lubricate is of less evaporation and consumption. Manual lubrication:Manual operates the pneumatic lubrication pump.It is of simple operation and can lubricate in the process of both operation and stop of pellet mill.

- 5.Processing of gear box:CNC processing with high accuracy,low operation noise and long service time.

- 6.It is equipped with safe protection mechanism.When operating overload,it could be quickly unload and protect the pellet mill effectively.

- 7.Screw feeder with anti-arch,make the raw material with poor liquidity feed smoothly.

- 8.Conditioner:adjust moisture and evenness of raw material to improve the capacity and improve the formation of pellets (optional).

- 9.Cutting mechanism equipped on the gate to control the length of pellet.

- 10.Siemens motor,imported bearing.

Technical Parameters of Rice husk Pellet press

Model | Capacity (t/h) | Power (kw) | Inner diameter of die (mm) | Pellet size (mm) | Dimension (mm) | Net weight (T) |

YPM250 | 0.1-0.2 | 15 | 250 | Ø6,Ø8,Ø10 | 1420*1200*1400 | 1 |

YPM320 | 0.3-0.5 | 37 | 320 | Ø6,Ø8,Ø10 | 2200*1000*1900 | 2.5 |

YPM350 | 0.5-0.8 | 55 | 350 | Ø6,Ø8,Ø10 | 2500*1100*2000 | 3.5 |

YPM420 | 1-1.5 | 110 | 420 | Ø6,Ø8,Ø10 | 2800*1150*2100 | 4 |

YPM520 | 1.5-2.5 | 160 | 520 | Ø6,Ø8,Ø10 | 3200*1500*2500 | 5 |

YPM660 | 2.5-3.5 | 185 | 660 | Ø6,Ø8,Ø10 | 3600*1700*3300 | 6 |

YPM800 | 3.5-5 | 250 | 800 | Ø6,Ø8,Ø10 | 3900*1800*3200 | 8 |

Types Of Rice husk Pellet press

Yongli Machinery is mainly engaged in producting and marketing rice husk pellet press, our product can be used for pelletizing various rice husk.

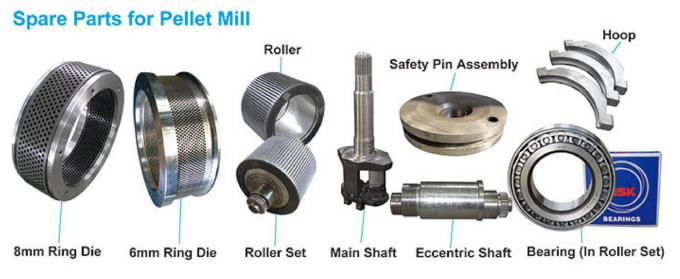

Rice husk pellet press Spart Parts Service

As a manufacturer focusing on the rice husk pellet press, in order to ensure the interests of users and high-efficiency operation of equipment, Yongli always provide spare parts for the rice husk pellet line supply services. It is including ring die, rollers, bearings, hammer, screens, fly cutter, buckets etc. All spare parts of the equipment are complete in model, reliable in performance, stable and durable, so as to ensure that customers’ spare parts replacement needs can be met in a short time and reduce user downtime for maintenance.

Ring Die Compression Ratio Of rice husk pellet press

- Users had better to know the compression ratio of the ring die for the pellet press. You may know the compression ratio refers to the ratio of the effective working length of the ring die to the diameter of the die hole.

- Yongli specializes in rice husk pellet press, here we’d like to provide you some advice.The compression ratio of the ring die of the pellet press can be selected according to the raw material formula and product requirements. Here is a few suggestions: The compression ratio of rice husk is 1:5.5~1:7

Pellet Raw Material Requirements

- Different types of raw materials, physical state, moisture content, presence or absence of impurities etc various factors will affect the selection of the sawdust pellet machine. In this way, for different materials, different pretreatment processes are required before entering the rice husk pellet press.

- If rice husk is clean and dry, it can be directly fed into the rice husk pellets equipment for granulation, if it has impurities, it needs pre-cleaner to remove impurities. If the moisture content is too high, it needs to be dried firstly before coming into pellet mill.

- Generally, the pre-treatment process required includes:cleaning, drying, crushing etc.

Videos for rice husk pellet press line