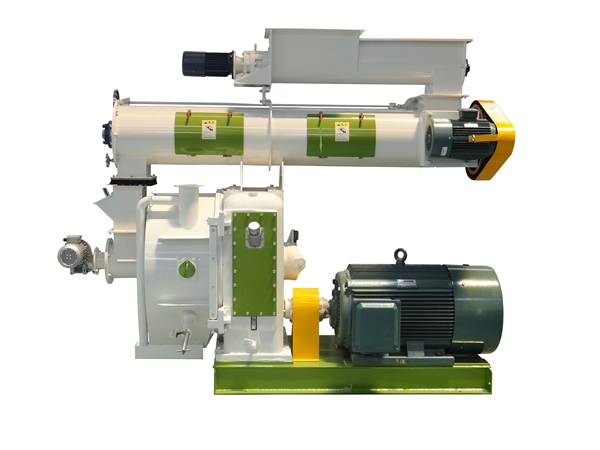

5t/h Wood Pellet Machine

Wood pellet machine is also be called wood pellet maker, wood pellet mill, wood pellet press, wood pelletizer Machine, wood granulator, wood pellet making machine, etc. It is mainly used for processing wood pellets. It is mainly used for processing biomass pellets. The equipment has the characteristics of strong power, high production efficiency, high reliability and low power consumption. It is an indispensable pellet forming equipment for biomass fuel industry.

wood pellet machine

Wood pellet machine be also called wood pellet maker, wood pellet mill, wood pellet press, wood pelletizer Machine, wood granulator, wood pellet making machine, etc. It is mainly used for processing wood pellets.

The equipment has the characteristics of strong power, high production efficiency, high reliability and low power consumption.

The max. capacity of our wood pellet machinen for one unit is 5t/h, the model is YPM800, power is 250kw. If you ask for 30t/h biomass pellet production line, we can make the best design for you and the biomass pellet maker will be used 6 pcs to realize this capacity, welcome to contact with us for more details if any questions to ask, you can contact us by whatsapp: +86 15190513782 and Whechat: +86 18961421248.

rief introduction for wood pellet machine

- YONGLI supply the wood pellet machine with capacity ranges from 0.1t/h to 5t/h.

Technical Parameters

Model | Capacity (t/h) | Power (kw) | Inner diameter of die (mm) | Pellet size (mm) | Dimension (mm) | Net weight (T) |

YPM250 | 0.1-0.2 | 15 | 250 | Ø6,Ø8,Ø10 | 1420*1200*1400 | 1 |

YPM320 | 0.3-0.5 | 37 | 320 | Ø6,Ø8,Ø10 | 2200*1000*1900 | 2.5 |

YPM350 | 0.5-0.8 | 55 | 350 | Ø6,Ø8,Ø10 | 2500*1100*2000 | 3.5 |

YPM420 | 1-1.5 | 110 | 420 | Ø6,Ø8,Ø10 | 2800*1150*2100 | 4 |

YPM520 | 1.5-2.5 | 160 | 520 | Ø6,Ø8,Ø10 | 3200*1500*2500 | 5 |

YPM660 | 2.5-3.5 | 185 | 660 | Ø6,Ø8,Ø10 | 3600*1700*3300 | 6 |

YPM800 | 3.5-5 | 250 | 800 | Ø6,Ø8,Ø10 | 3900*1800*3200 | 8 |

Application fields

Wood pellet machine is widely used in biomass energy, such as fuels plant, wood processing plant,fertilizer plant, power station etc. We can produce the biomass pellet mill and full complete biomass pellet line, capacity ranges 1t/h-100t/h, welcome to contact with us.

Raw materials

Biomass Pellets

Maintenace of the Wood pellet machine

The maintenance of the wood pellet machine mainly includes the disassembly and assembly of the granulator and the replacement and repair methods of vulnerable parts. The disassembly and assembly of the granulator includes four parts: disassembly and assembly of the feeding system, disassembly and assembly of the conditioning system, disassembly and assembly of the main transmission system of the granulator, and disassembly and assembly of the inclined groove system. Remove the fasteners between the feeding system, mixing system, main transmission system, and chute system to divide the granulator into four parts.

How to start the wood pellet machine?

After all the test runs are normal, the official driving can be carried out. When driving, attention should be paid to the order of starting up, which should be from bottom to top. The steps are as follows:

(1) Carry out inspection work according to the steps of the test run.

(2) Drain the condensate from the steam pipeline and adjust the steam pressure (0.2-0.4 MPa).

(3) Start the main motor.

(4) Start the tempering motor.

(5) Start the feeding motor and adjust the feeder to the lowest speed.

(6) Open the discharge door and simultaneously open the steam inlet valve. Adjust the feeding motor speed slightly. After pressing out the particles, gradually adjust the feeder speed and steam addition amount to the appropriate level.

(7) Adjust the cutting blade to make the particle length suitable.

(8) Further adjust the speed of the feeder to achieve the rated current of the main motor, and adjust the steam flow accordingly to ensure appropriate temperature and humidity.

Biomass Wood pellet machine production line project

Video