Showing 25–36 of 78 results

-

Features 1.Inlet sleeve for dust-laden air and outlet flange for clean air. 2.Bottom part with cleaning flap,and lock fitting piece. 3.Efficiency of separation: more than 98%. Technical Parameters

-

Features The fly knife is suitable for all of our wood chipper. Different modle with different size. Picture of Wood chipper Picture of Fly knife

-

-

Features It is commonly used in forging smelting furnace and high pressure forced ventilation ,and transporting materials, transportation air and gas with noncorrosive,non hypergolic. Technical Parameters

-

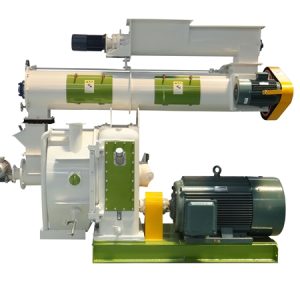

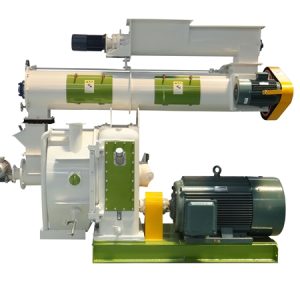

- Yongli Machinery specializes in the production of grass granulator, which also be called grass pellet mill, grass pellet machine, grass pelletizer, grass pellet making machine etc, a single output of 1t/h -5t/h. If you ask for 50t/h pellet line, we will design with 10pcs grass granulator at the same time.

-

- 1.Forced feeder:Forced feeding into pelletizing chamber,make pellet mill operate stable and with high efficiency.

- 2.Gear reducer with Aluminum Alloy housing,wilth compact structure,altractive appearance and high driving efficiency.

- 3.Driven by gear,elegant and efficient gearbox grants pellet mill with high driving efficiency.

- 4.Lubrication system consists of automatic lubrication and manual lubrication. Automatic lubrication system:lubricated by thin oil and is free of labor force.Lubricate can automatically cool down during operation.Oil recycle used can cool the oil.Lubricate is of less evaporation and consumption. Manual lubrication:Manual operates the pneumatic lubrication pump.It is of simple operation and can lubricate in the process of both operation and stop of pellet mill.

-

1. Shape: single head single hole, double head double hole.

2. Size: various sizes, customized.

3. Material: high quality alloy steel, wear-resistant steel.

-

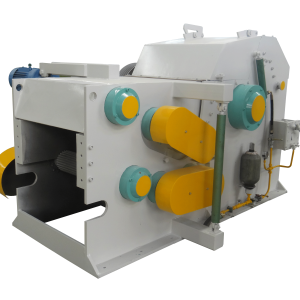

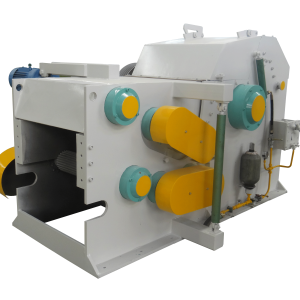

Wood chipper shredder is an ideal chipper machine to process wood logs, wood timber, bamboo, watse wood into wood chips. It equipped with feeding system equipment, the body of wood chipper shredder, bracket belt conveyor, Electrical Control system, hydraulic system, etc.It is very easy to operate.

-

Woodchips pellet mill, we can also call it woodchips pellet machine, woodchips pelletizer, woodchips granulator, woodchips pellet making machine, etc

-

Sugarcane Bagasse dryer machine is the best choice to dry bagasse materials of high moisture content.

Sugarcane Bagasse go through dryer can reach Sugarcane Bagasse moisture at 10-15%.

Our dryer plays an important role in drying process of Sugarcane Bagasse pellet production line.

-

- Model:YHM27*25, power 15kw

- Available raw material: wood bricks , shavings, straw, peanutshell, palm shell ,cotton seed, bamboo dust, rice husk, elephantgrass, sugar cane, pulp, olive dust, and so on.

-

- Available raw material: wood logs with barks.

- Famous brand tooth surface, with high driving efficiency and long service time.

- Debarker roller is directly connected with reducer, with stable operation,easy maintenance.

- Debarking knived are arranged in screw type, with high debarking efficiency.

- Equipped with belt conveyor at the bottom of wood debarker, it setsto collect&convey barks.

- Seperated type side board, itmakes maintenance more convenience.

- It could be customized accarding to raw material diameter and length.